Development of a color biocompatible coating film recognizable to the naked eye

| Development of a color biocompatible coating film recognizable to the naked eye |

|

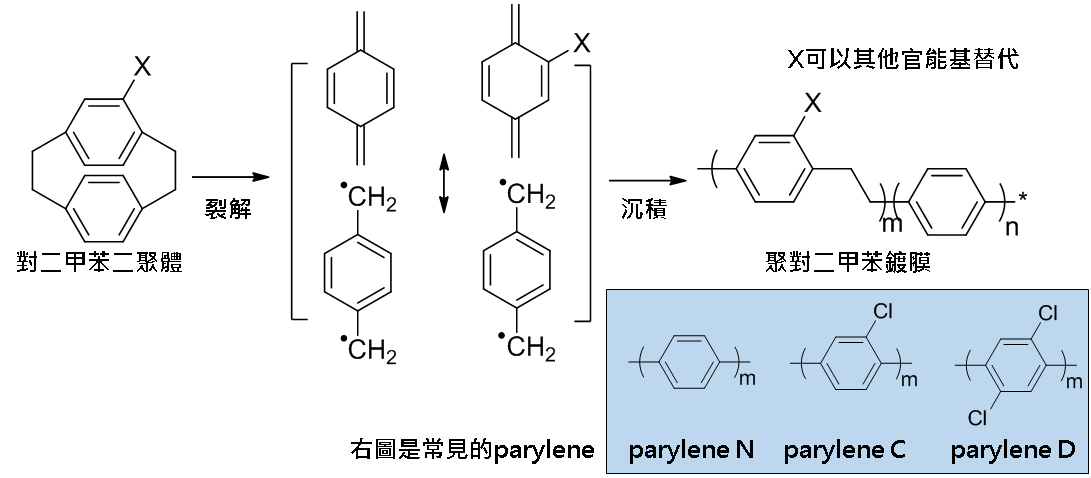

Prof. Sheng-Tong Huang of Chemical Engineering and Biotechnology Materials with biocompatible properties and excellent mechanical properties are the most basic requirements for the development of medical products, but directly developing materials with both excellent mechanical and biological properties is a time-consuming and costly study. At this time, the biocompatible material is directly coated on the surface of the material with excellent mechanical properties to directly endow the whole material with biocompatibility and retain the mechanical properties of the original material. Para-xylene dimer (〔2.2〕paracyclophane) has the characteristics of biocompatibility and can be applied to the surface structure of the material, and it has begun to emerge in the field of biomedical product coating. The para-xylene dimer monomer molecules are polymerized into a poly-p-xylylene (also called parylene) polymer film by chemical vapor deposition (CVD) polymerization. The polymer film produced by the manufacturing method has many advantages: it is suitable for the surface of various materials, can form molecular-level films on various three-dimensional structure surface materials, and the film formation process is carried out at room temperature without residues of organic solvents; The polymer film has good biocompatibility*, can resist the penetration of water vapor, and can modify the functional group on the monomer and then polymerize, so that the material coating surface has special functionality (see Figure 1). Because the poly-p-xylene polymer film has the above-mentioned characteristics of biocompatibility, and it has the characteristics of resistance to moisture, chemical corrosion, and insulation, etc., such film coating materials have been used for more than 20 years and have been used in various Medical products, electronic components, and semiconductors are all standard cladding materials; in recent years, such films have played a higher application value in the field of biomedical materials products, and the chemical vapor deposition process can be applied The equipment of various three-dimensional structures and materials shows the application and practicality in medical equipment. |

|

Figure (1), Schematic diagram of para-xylene dimer monomer molecules and the coating by chemical vapor deposition |

|

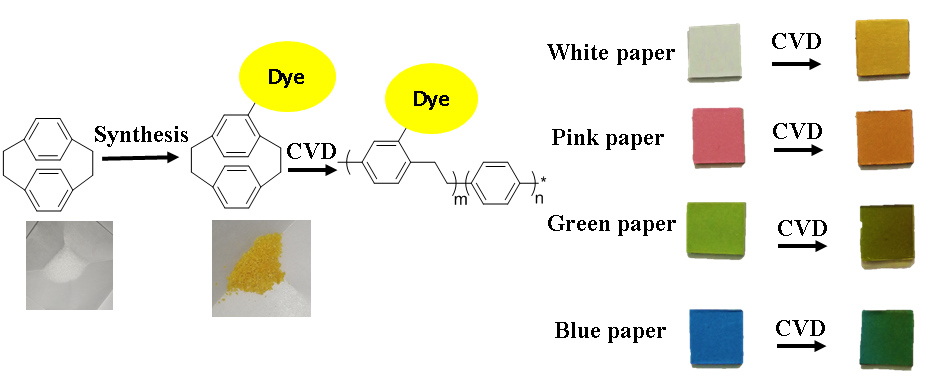

Bio-medicine and electronic products are coated with poly-p-xylene polymer film, which has developed para-xylene dimer monomer molecules with different special functional groups. In addition to the common parylene-N, the commercialized parylene-C and parylene-D are modified with functional groups in para-xylene dimer monomer molecules and then synthesized and polymerized into poly-para-diene by chemical vapor deposition. Toluene films, these films can make the surface of the material have different effects, but the common point of these films is that they are all transparent and colorless films, which makes them need to use professional and expensive testing equipment when initially testing the coating results, so when they are in When mass-produced, defective products cannot be quickly picked out. Our goal is to develop a film that can distinguish colors after the polymerization and retain the properties of poly-p-xylene polymer film. Films that are color and can be recognized by the naked eye are very important concepts. The errors in the formation of the surface-coated film can be found directly by the naked eye instead of professional identification equipment. This can provide user convenience and engineers can After the process is completed, directly confirm the film synthesis. Doctors perform invasive medical behaviors using products coated with a polymer film of color poly-paraxylene that can be recognized by the naked eye and can also confirm with the eyes that the medical products used are coated with poly-paraxylene before performing medical behaviors. Molecular film coating to avoid implanting non-biocompatible medical products into the human body without a successful polymer film coating. Also, the colors can be used to identify the use of materials, device usage, and timing, such as order, orientation, and palm directionality. Under a large number of cumbersome medical behaviors, frequent misuse can be avoided. To achieve this goal, we will first develop para-xylene dimer monomer molecules required for color recognition chemical coatings. The concept is shown in figure (2). We use the colored functional group as a dye, modify it on the para-xylene dimer monomer molecule by chemical synthesis, and use the chemical vapor deposition method to give the original It is a transparent film color. We have developed a bright yellow para-xylene dimer monomer molecule, and expect that the coating will be deposited on the surface of various materials to create a color recognition function. In the picture (second) we show the newly synthesized yellow para-xylene dimer monomer molecule, which is formed into a thin film by chemical vapor deposition (picture 2 right). We coated yellow film on the surface of white paper and ternary color paper to show the color mixing results of our coating and other color substrates. Based on the ternary color of light, we infer that when white and yellow are yellow, red, and yellow are orange, green, and yellow are khaki, and blue and yellow are green, and the results are in line with expectations. We have successfully developed colored para-xylene dimer monomer molecules and successfully demonstrated that the colored monomer molecules can be formed into a film that can be visually recognized by chemical vapor deposition. This research will help to quickly pick out the defective products by the naked eye when a large number of chemical coatings are made, and prevent the unfortunate medical negligence caused by doctors using medical products without biocompatible coatings when performing medical actions. |

|

Figure (two), the color mixing results of yellow para-xylene dimer monomer molecules and yellow coating *(The US FDA regulates the use of certain medical devices, such as surgical devices, implantable medical devices, electronic medical devices, etc.). |