Enhancing supply chain resilience and efficiency of HVAC systems in semiconductor manufacturing facilities using graph-based large multimodal models

Enhancing supply chain resilience and efficiency of HVAC systems in semiconductor manufacturing facilities using graph-based large multimodal models.

By Assistant Professor Chi-Yun Liu of Department of Civil Engineering

Background and Critical Importance of SMFs.

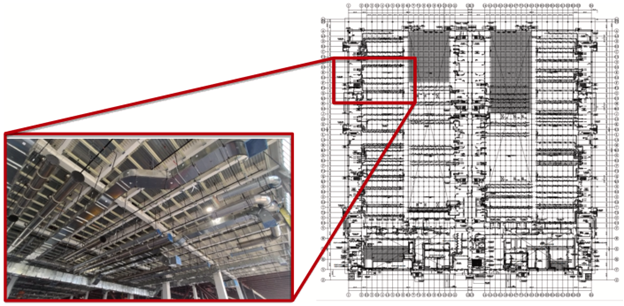

Semiconductor manufacturing facilities (SMFs) are among the most technologically advanced and energy-intensive industrial environments in the world (Figure 1). They rely on highly specialized Heating, Ventilation, and Air Conditioning (HVAC) systems that must maintain ultra-strict environmental parameters: temperature stability to 0.1 °C, minimal variation in humidity, and compliance with ISO Class 1 cleanroom particulate standards (Figure 2). Such precision is non-negotiable; however, small environmental perturbations can significantly degrade photolithography, resulting in a 20 % decrease in chip output and associated losses of millions of dollars each day. As a result, HVAC technology is not just a utility for people but a critical infrastructure for the semiconductor manufacturing industry, ensuring continuity and quality in semiconductor production.

Fig. 1. The image (left) shows the complex HVAC system with multiple ducts and pipes. The image (right) shows the AutoCAD model with the complexity of the HVAC duct and piping systems.

Fig. 2. The image (left) shows the installation of HVAC components inside the fab building. The image (right) shows the outside view of the fab construction site.

Existing Vulnerabilities in Supply Chain.

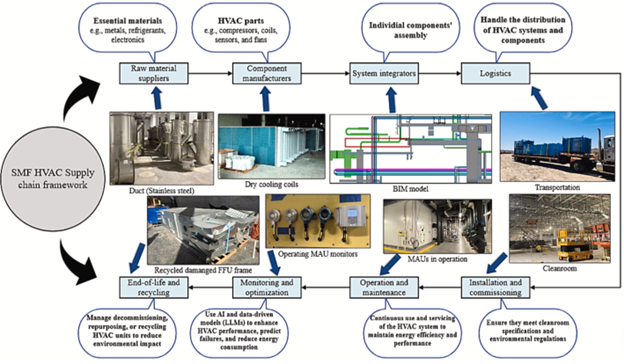

The HVAC supply chain servicing SMFs is uniquely complex, relying on an assemblage of highly specialized components, ranging from high-efficiency particulate air (HEPA) filters to chip-integrated flow sensors, most of which originate from a limited number of globally dispersed suppliers (Figure 3). More recent disturbances, not least the Covid-19 pandemic, have revealed glaring weaknesses, doubled lead times for major components, and highlighted the fragility of traditional manual or static supply chain management (SCM) paradigms. Existing Artificial Intelligence (AI) solutions, while good in other broad logistics settings, may not have the domain-specific intelligence needed for SMFs, especially in supporting rigorous regulatory compliance, extreme energy consumption (40-60% of total facility power), and the complex interdependencies among the HVAC subsystems. This fragmented reality makes SMFs vulnerable to cascading failures, in which the delay of a single component can immobilize multi-million-dollar fabrication lines.

Fig. 3. SMF HVAC supply chain framework.

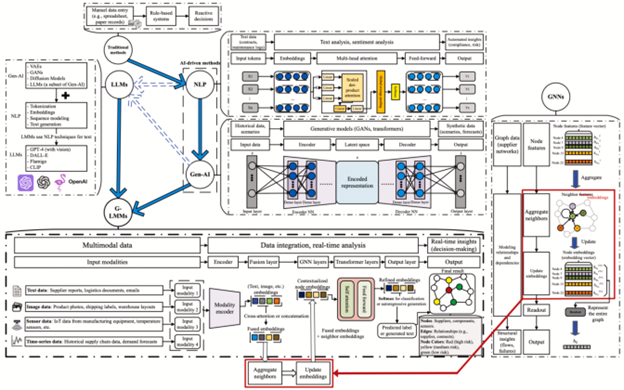

Proposed G‑LMM Framework.

To overcome such limitations, this study offers the Graph-based Large Multimodal Model (G-LMM). This is an integrated framework that represents a paradigm shift in SMF SCM by combining the semantic reasoning capabilities of Large Language Models (LLMs) with the relational modeling capabilities of Graph Neural Networks (GNNs). Unlike traditional AI models, which mostly break down individual structured datasets into numerical values, the G-LMM incorporates various types of multimodal data (e.g., sensor data, maintenance records, technical data, supplier contracts, regulatory data) into a unified, context-rich representation. Through GNNs, the model captures complex graph-structured relationships among suppliers, HVAC components, and operational nodes, thus providing a complete picture of system dynamics and supply chain risks.

Major Developments & Innovations in Methodology.

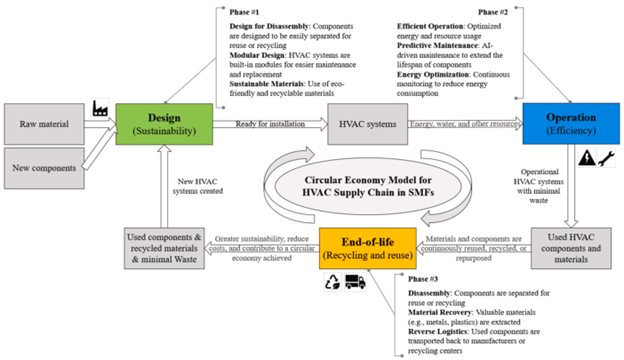

The G-LMM framework focuses on three key operational improvements: 1. Real-Time Anomaly Detection: By modeling relationships among components using GNN layers, the framework identifies deviations from expected operational patterns, including impending failures or supply disruptions, before they cause production loss. 2. Automated Compliance and Document Monitoring: The framework enhances compliance transparency and agility by automating the monitoring of technical documentation, handling revisions, and ensuring compliance across the supply chain. This ability enables easy, efficient communication among field engineers, remote analysts, and compliance officers, reducing human error and minimizing response latency. 3. Circular Economy Integration: The newest development that enables the framework to track the lifecycle of the HVAC materials (Figure 4). By identifying the end-of-life stage of key components, the G-LMM promotes resource recovery, recycling, and efficient reverse logistics, reducing the need for virgin material and promoting sustainable manufacturing practices.

Fig. 4. Circular economy model for HVAC supply chain in SMFs.

Research Objectives/Significance.

The main goal in this research is to optimize HVAC SCM in the design and construction, installation, maintenance, and operation (DCIMO) lifecycle. We move away from reactive maintenance toward proactive, G-LMM-driven decision support that integrates operational data and technical documentation through interactive dashboards and analytical interfaces (Figure 5). The framework hopes to improve supply chain resilience, ensure operational reliability, and meet the growing demand for high-end semiconductors worldwide by leveraging these AI-driven capabilities. In so doing, this study makes the G-LMM a transformative approach that integrates siloed data streams into contextual, actionable information, thereby gaining a strategic advantage in sustaining 24/7 semiconductor manufacturing operations.

Fig. 5. Transformative processes from traditional and AI-driven methods to G-LMMs.

Conclusion and Implications for the Future.

Simulation-supported evaluations of the proposed framework have shown significant increases in predictive accuracy, responsiveness, and operational visibility. Future research will focus on making operational SMF data live to provide additional evidence of the framework's empirical impact on resilience, cost-efficiency, and energy performance. Additionally, this work outlines opportunities to scale G-LMMs to other industries that are sensitive to precision developments, such as pharmaceutical production and aerospace, as well as to combine them with disparate elements of vast Industry 6.0 ecosystems, including the Internet of Things (IoT), digital twins, and advanced robotics. As one of the first approaches to bring together graph-based reasoning with AI-based HVAC initiatives toward SMFs, the suggested framework represents a crucial step toward more adaptive, sustainable, and intelligent supply chains for the semiconductor industry and many others.