National Taipei University of Technology flexible electronic packaging factory laboratory successfully developed ultra-high water-barrier film

|

National Taipei University of Technology flexible electronic packaging factory laboratory successfully developed ultra-high water-barrier film |

|

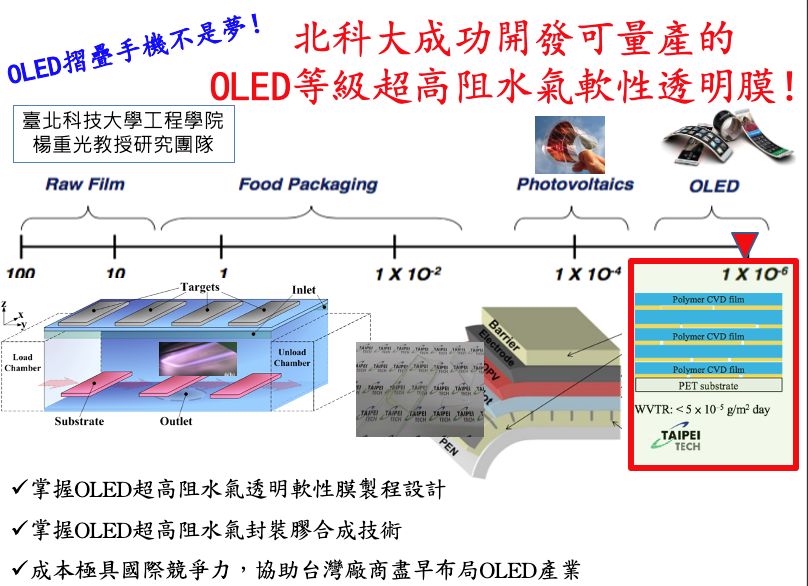

Vice Principal Thomas C.K. Yang According to different flexible electronic devices, the requirement of the water vapor permeability of the barrier film varies significantly for the packaging industry. The water vapor transmission rate (WVTR) of a water barrier film is defined as the amount grams of moisture transmits a film per square meter per day (g/m2/day). For example, 10-2 (g/m2/day) means that only bottled water of 1L per day penetrates the barrier film with the area of a football field (50 m X 100 m). 10-5 (g/m2/day) means that only one drop of water per day can pass through a barrier film with the size of a football field. Therefore, the lower water vapor permeability of the water barrier gas film, the stricter development of the water barrier film. Comparing to other industries or other electronic products, OLED has the most stringent requirements for the water barrier film. Only less than 10-5 g/m2/day, the barrier film for OLED can have market benefits. Most water barrier films currently available in Taiwan are 10- 2 ~ 10-3 (g/m2/day) by the test of the flexible electronic packaging team of National Taipei University of Technology. However, our team in NTUT has successfully developed water barrier films of WVTR of 10-5 (g/m2/day). The latest marketing statistics from IDTechEx in the United Kingdom predicted that the flexible transparent barrier film for electronic components the market would require more than 913 million US dollars by 2027. By 2029, the area needed for OLED will exceed 50 million square meters. The laboratory in NTUT expects that our products developed will be based on the Taiwan market and look internationally. |

|

|

Figure 1. The development team and R&D technology milestone of the ultra-high water-barrier film commercialization process for flexible electronic commodities at National Taipei University of Technology. |

|

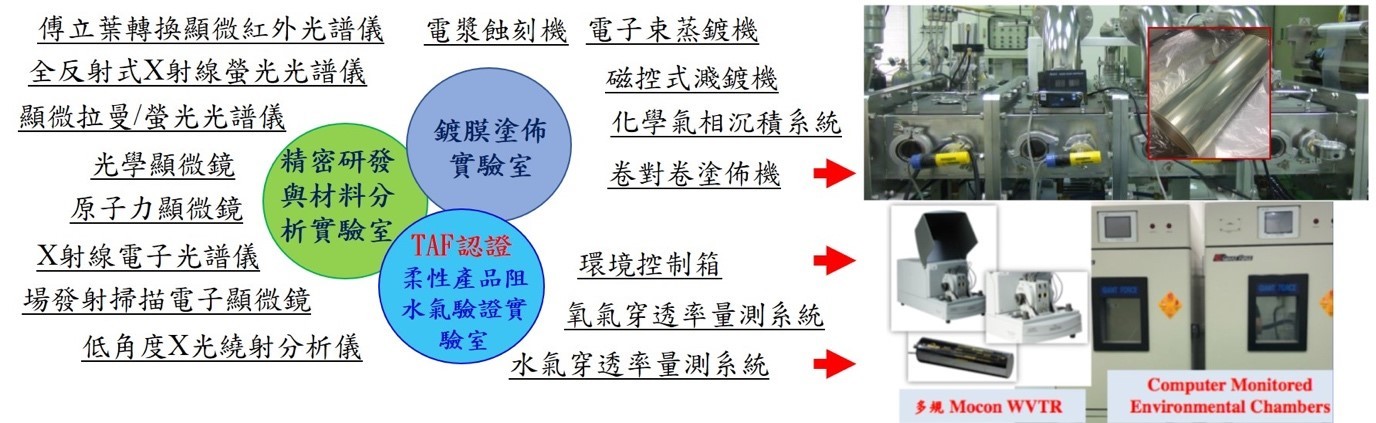

The electronic packaging team is constituted by professors from the College of Engineering. The main members include Dr. Thomas Chung-Kuang Yang, Dr. Sheng-Tung Huang, and Dr. Kun-Li Wang. From November 2014 to October 2019, the team has received a grant of 21 million from the Ministry of Science and Technology for five years to develop flexible ultra-high water barrier film for electronic devices. During this period, the process technology developed by the team evolving from the first-year Batch-to-Batch batch process to the third-year Tray-to-Tray mass production batch process. The water vapor transmission rate (WVTR) of the developed water barrier film has been improved from 10-2~10-3 g/m2/day in the first year to 10-5 g/m2/day in the third year. The transmission rate has increased from 71% to 91%. All the data show that the ultra-high water barrier film from the NTUT team has market advantages. The measured value of the water barrier (WVTR) of the available water barrier film in the Taiwan market was only about 10- 2 g/m2/day. In the fourth year, in addition to the development of the high barrier water vapor process, the mass-produced In-Line process was also tried. In the fifth year, the Roll-to-Roll wet process and the In-Line dry process also applied to manufacture the barrier films, which were ready for making commercial products. In 2018 and 2019, the research team not only successfully transferred the technology to the companies but also possessed four patents related to the water-barrier gas film. The patent numbers were I649197, I629180, I606934, and I602693. After the affirmation of the Ministry of Science and Technology, the team also obtained the premise value creation project “The commercialization of the roll-to-roll process” from the Ministry of Economic Affairs in 2018. Based on the achievement of the premise project, the value creation project “The packaged A+ flexible high water barrier film” was successfully granted by the Ministry of Economic Affairs during 2019-2021 with a total of 20 million NTD. It is expected that the roll-to-roll mass production process can be transferred to a company in 2021. Not only the process and materials are under control by the team, but the price is more internationally competitive! Since our laboratory already developed high-barrier water gas films, we were currently committed to optical defect detection. The correlation of the defect and water vapor transmission rate can speed up the understanding of the WVTR of a film (usually, it takes two days to measure WVTR). This team can achieve the prosperous results not only because of the diligent and conscientious students but also because of possessing the complete process, testing, and water barrier verification equipment. The thin film deposition laboratory has magnetron sputtering deposition, electron beam evaporation deposition, and the roll-to-roll deposition instruments for developing the innovative processes of water barrier films. The center of precision research and material analysis has a number of optical instruments, such as Fourier transform microscopic infrared spectroscopy (FTIR), micro Raman (Raman) spectroscopy, Ultraviolet-visible (UV-Vis)spectroscopy, etc., and a variety of surface detection instruments, including X-ray electron spectroscopy (XPS), field emission scanning electron microscope (FESEM), atomic force microscope (AFM), etc. can be used to characterize the water barrier films. The first TAF certified flexible high barrier film test center was successfully established in Taiwan. This center provids a multi-spec water vapor transmission rate measurement(WVTR), oxygen transmission rate measurement (OTR), and the environmental control box, which can be used in high-temperature and high-humidity environments to measure WVTR, for example, electric automobile packaging. In response to the needs of the wearable devices and flexible electronic packaging materials industry, this testing center provides service for the related fields such as OLED displays, OLED lighting, quantum dot LCD TVs, electronic tags, flexible photovoltaic cells, wearable devices, and flexible electronic products, etc. The center could enhance the R&D energy of flexible electronic barrier films, provide consultation and assistance for small and medium enterprise (SME) upgrade and added-value technology, create the pioneer R&D and service of flexible electronic products for the next generation in Taiwan, regardless of design, testing or water-barrier verification in the future. It can provide a common platform for Taiwan academics and SMEs to develop new generations of flexible electronic devices. |

|

|

Figure 2. Relevant technologies, equipment and laboratories established by the ultra-high water-blocking gas film team of flexible electronic commodities at Taipei University of Technology. |